Heat Treatment Processes

Price 25000 INR/ Kilograms

MOQ : 1000 Kilograms

Heat Treatment Processes Specification

- Product Name

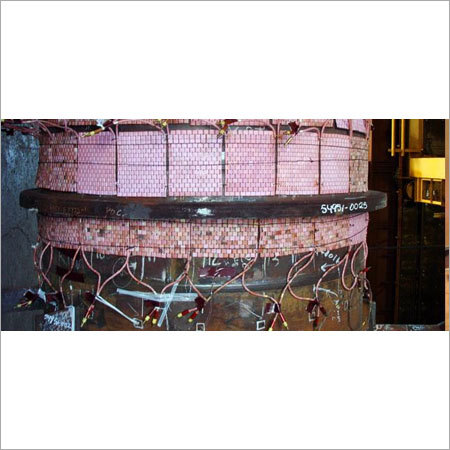

- Heat Treatment Processes

- Application

- To alter physical and chemical properties of materials

- Quenching Media

- Water, Oil, Polymer

- Size Range Treated

- From small components to large castings

- Surface Hardness Achievable

- Up to 62 HRC

- Atmosphere

- Controlled (Air, Vacuum, Inert Gas, etc.)

- Batch or Continuous Operation

- Both available

- Quality Inspection

- Microstructure analysis, Hardness testing

- Process Control

- Fully automated or manual

- Tolerance

- +/- 0.01 mm

- Type

- Industrial Process

- Modes

- Annealing, Normalizing, Hardening, Tempering, Carburizing, Nitriding, Cyaniding

- Cooling Rate

- Variable as per process

Heat Treatment Processes Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- Supply Ability

- 10 Kilograms Per Week

- Delivery Time

- Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- East India, Odisha, West Bengal

- Certifications

- ISO 9001:2015

About Heat Treatment Processes

Since the establishment in the year 1998, we, Super Heat Treatment Plant, are considered as a credited service provider of General Heat Treatment Processes at Kolkata, India. Under the services or process, different types of work is done by our adept professionals under the stern guidance of well-versed experts. Quick execution, diligent workforce, reliability and cost-effectiveness are some of the unmatched attributes of the General Heat Treatment Processes services.

Following processes is done under this service:

- Stress Relieving

- Annealing (Full Annealing, Process Annealing, Isothermal Annealing Spheroidise Annealing)

- Stepped Quenching

- Tempering

- Austempering

- Martempering

- Flame Hardening

- Solution Treating

- Precipitation Hardening (Natural/Artificial Ageing)

- In situ Stress Relieving (with time-temperature recorder arrangement)

Advanced Process Control for Optimal Results

Our heat treatment processes can be fully automated or manually managed to ensure high precision and repeatability. By tailoring control methods to your specific production requirements, we deliver consistent quality, whether you need a single batch or continuous operation. Flexible process control is instrumental in achieving exacting standards and streamlining production workflows.

Diverse Treatment Modes and Controlled Atmospheres

We offer a spectrum of treatment modes, including annealing, normalizing, hardening, tempering, carburizing, nitriding, and cyaniding. Each process is executed in a controlled atmosphereair, vacuum, or inert gasto meet diverse material transformation needs. This versatility allows the service to optimize the materials microstructure and surface attributes across industrial applications.

Precision and Scalability in Heat Treatment

With capabilities to treat parts ranging from small components to large castings, our process accommodates various industry requirements. Surface hardness achievable is up to 62 HRC with a tight tolerance of +/- 0.01 mm. Whether for automotive, aerospace, or manufacturing applications, our heat treatment services deliver robust durability and mechanical properties across different scales.

FAQs of Heat Treatment Processes:

Q: How is process control maintained during heat treatment services?

A: Process control in our heat treatment is achieved through fully automated systems or manual oversight, depending on customer requirements. Both approaches ensure precise temperature, atmosphere, and timing adjustments to consistently meet specification standards.Q: What types of heat treatment modes are available and what are their uses?

A: We provide annealing, normalizing, hardening, tempering, carburizing, nitriding, and cyaniding. Each mode serves specific purposes, such as refining grain structure, increasing hardness, improving wear resistance, or enhancing toughness, tailored to your materials application.Q: Where are heat treatment processes typically performed, and in what atmosphere?

A: Our services are conducted in controlled environments using air, vacuum, or inert gases, based on process requirements. This helps to prevent oxidation, contamination, and ensures superior surface quality for treated components.Q: When should heat treatment be applied to industrial components?

A: Heat treatment is recommended when materials require enhanced physical or chemical properties, such as after casting, forging, or machining, or to achieve specific surface hardness and durability for critical applications.Q: What is the size range of components that can be treated?

A: We accommodate a broad size spectrum, treating everything from small precision parts to large castings, ensuring flexibility for various industry sectors and component specifications.Q: How is quality assured in the heat treatment process?

A: Quality assurance is conducted through microstructure analysis and hardness testing. These inspections verify that treated components maintain the desired mechanical properties and meet specified tolerances after processing.Q: What are the benefits of using variable quenching media and cooling rates?

A: Customizing quenching media (water, oil, or polymer) and cooling rates allows us to achieve targeted mechanical properties for different materials, minimizing defects and optimizing performance for specific industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry